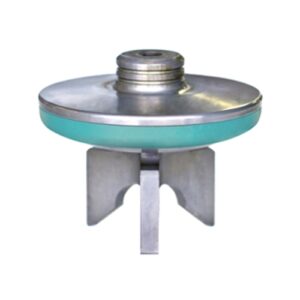

Plunger Packing (SPM)

Plunger packing plays an integral role in sealing pumps and maintaining adequate downstream pressure. In plunger pumps the packing is held stationary inside a stuffing box; in piston-style pumps, the packing sits in a groove.

CSS proved its specialty in-house packing solutions designed for specific environments. Depending on the application, we can create different types of seals to reinforce the packing, fill voids, and extend the service life of the plunger.

Our specialty packing materials and serviceability include:

Type-A

- Material: Medium-hard, black nitrile (NBR) with synthetic fabric around a rigid phenolic core; three sets of pressure rings, each with a top and bottom adapter for effective sealing.

- Compatibility: General-service packing used in all types of industries; resistant to hydrocarbons, water, mild acids, temperatures up to 180° F for Metal Plungers and 150 °F for ceramic plungers, pressures up to 2,500 psi

- Note: For really hot water or greater acid resistance, upgrade to 0858 super gold packing, which is able to withstand temperatures up to 300 °F and pressures up to 5,000 psi

Type-B.

- Material: Soft, black nitrile (NBR) with synthetic fabric and homogenous ID lip around rigid phenolic core, used for power end packing; three sets of pressure rings, each with a top and bottom adapter for an effective seal

- Compatibility: Hydrocarbons, water, mild acids, temperatures up to 180 °F for metal plungers and 150° F for ceramic plungers, pressures up to 1,500 psi

Frequent packing servicing places additional strain on frac pumps and their components. Generally, packing has to be changed out/serviced at

approximately 200-250 hours of run-time, causing downtime and exposure time,

safety risks and costing operator’s money.

CSS plunger paking’s designed to give industry-leading performance in today’s

toughest high-pressure environments, directly translating to longer product life in all major shale plays. The increased asset utilization rate allows for packing to be

changed at the maintenance facility rather than an operator location, decreasing non-productive time and reducing exposure time for service technicians.